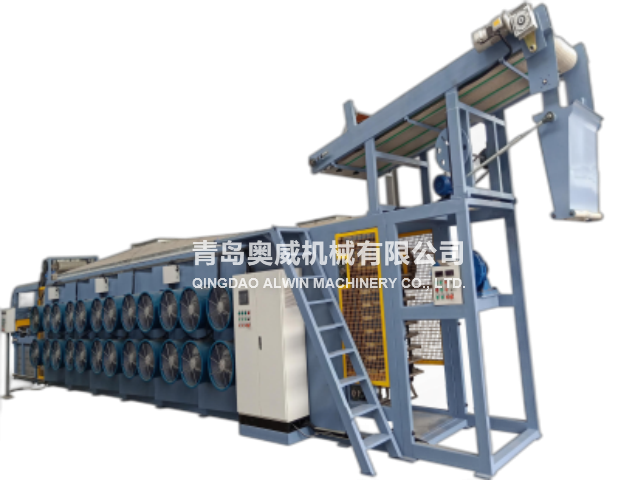

The machine can satisfy the requirement during mixing process of rubber sheet cooling,slicing and laminating,etc. Form automatic production line with internal mixer or dispersion mixer and double-cone screw automatic feeding sheeting mill or open mill to reach the effect of continuous production operation. The rubber sheet cooling mode can as per customer requirement adopt spray or immersion.