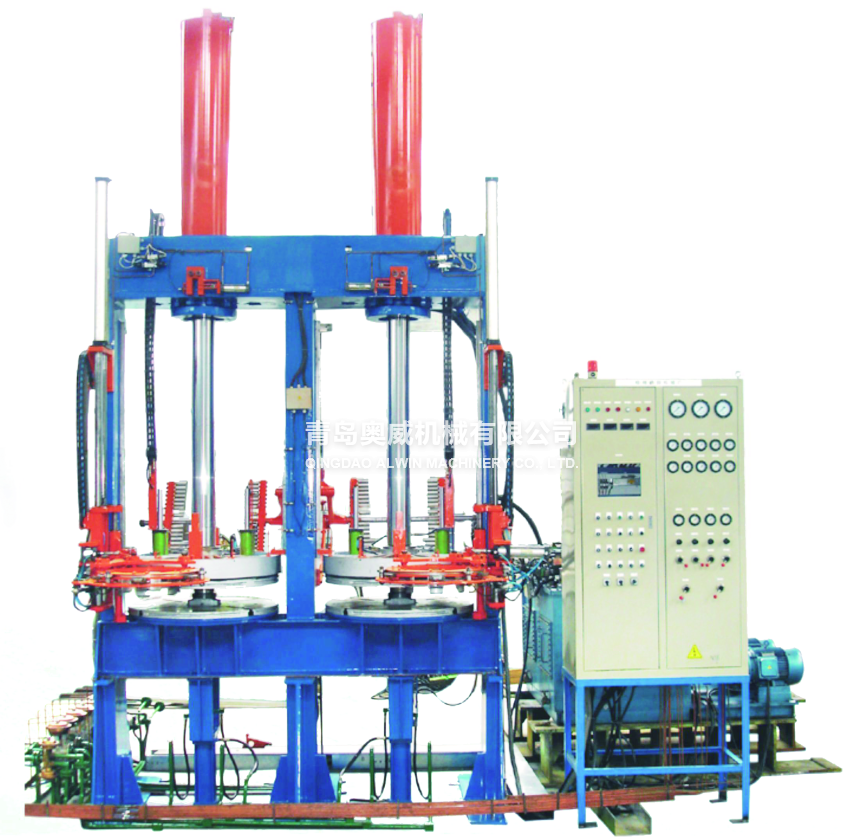

1.The product is characterized by double mold, frame type, independent unit, hot plate heating, full hydraulic type central mechanism, vertical rising and falling upper curing chamber (beam does not rise and fall) and top single cylinder pressure mold locking.

2.The machine is suitable for installing segmented mold and two piece mold. It is used to cure a new type of wide section and all-steel PCR tires with bead diameter of 12’’-24’’. It can meet the nitrogen and steam vulcanizing technology.

3.The customer can choose two positions four points post cure inflator, one position tire storing device, pneumatic or electric two positions tire storing device, pnematic or electric three pisitions tire storing device and so on.

4.The electrical control system adopts PLC as the core of real-time control. It uses insuatrial touchscreen as HMI which can set up, collect, save, alarm and check the parameter. It has Ethernet interface and supports the vulcanizing cluster network.

5.The hydraulic control system uses 1 hydraulic station to drive 1set or more than 1 set of curing press. The control of oil pressure and flow adopts proportional control technology.